Introduction to In-Space Assembly

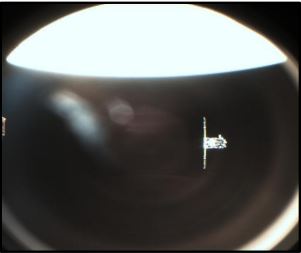

Picture: The roboticsystem Canadarm2, docking SpaceX’s Dragon to ISS. Credit: NASA

In-space assembly is revolutionizing how we approach space exploration and infrastructure. By enabling the construction and assembly of spacecraft and stations directly in space, we can overcome the limitations of launching fully assembled structures from Earth. This practice not only maximizes the efficiency and capabilities of space missions but also fosters international collaboration and innovation.

Notable Assembly Practices

- Assembly of the International Space Station (ISS): The ISS stands as a testament to the power of in-space assembly. Built through the cooperation of multiple countries, the ISS was assembled in orbit, piece by piece, over several years. This modular approach allowed for the integration of various components and systems from different nations, showcasing the potential of collaborative space assembly.

- Docking of Different Space Vehicles: The docking of various space vehicles, such as crewed spacecraft, cargo ships, and scientific modules, demonstrates the versatility and critical importance of in-space assembly techniques. These docking maneuvers require precision and coordination, further emphasizing the need for robust infrastructure and advanced technology.

Policy and Permissions

The practice of in-space assembly, particularly when involving mission extension vehicles (MEVs) and other servicing technologies, necessitates clear policies and permissions from satellite and spacecraft owners. Establishing a regulatory framework is essential to ensure the smooth operation and collaboration between different stakeholders in space.

Infrastructure for In-Space Assembly

- Modular Design: The future of in-space assembly relies heavily on modular design principles. By developing standardized modules, we can ensure compatibility and ease of assembly. These modules can be easily docked and undocked, much like connecting LEGO pieces, allowing for flexible and scalable space infrastructure.

- Innovative Docking Systems: Similar to how different countries have various electrical plugs, space docking systems must be versatile enough to accommodate various designs. Innovations in docking technology are crucial for ensuring that modules from different manufacturers can connect seamlessly.

- Robotic Arms: Robotic arms play a pivotal role in in-space assembly. These advanced tools are designed to handle a wide range of payloads, providing the dexterity and precision needed to assemble complex structures in the microgravity environment of space.

Interchangeable Module Models

To maximize the efficiency of rescue and maintenance missions, it is essential to develop interchangeable module models. For example, a rescue vehicle should be capable of assisting any space station, whether it is owned by a government agency or a private company. This interoperability ensures that resources can be efficiently utilized across various missions and platforms.

General Components

- Antennas and Solar Panels: These critical components must be designed for compatibility with a wide range of satellites and space vehicles. Standardizing the design of antennas and solar panels facilitates easier upgrades and replacements, enhancing the longevity and functionality of space assets.

- Smaller Components: Components such as LIDAR systems and small valves should also be designed with interoperability in mind. By ensuring that these smaller parts can connect to different satellites, we can streamline maintenance and assembly processes, reducing costs and increasing operational efficiency.

Conclusion

In-space assembly is paving the way for a new era of space exploration and infrastructure development. By focusing on modular design, innovative docking systems, and interoperable components, we can build a sustainable and efficient space environment. This collaborative approach not only enhances the capabilities of space missions but also fosters international cooperation and technological advancement.

Introduction to In-Space Assembly

In-space assembly is revolutionizing how we approach space exploration and infrastructure. By enabling the construction and assembly of spacecraft and stations directly in space, we can overcome the limitations of launching fully assembled structures from Earth. This practice not only maximizes the efficiency and capabilities of space missions but also fosters international collaboration and innovation.

Notable Assembly Practices

- Assembly of the International Space Station (ISS): The ISS stands as a testament to the power of in-space assembly. Built through the cooperation of multiple countries, the ISS was assembled in orbit, piece by piece, over several years. This modular approach allowed for the integration of various components and systems from different nations, showcasing the potential of collaborative space assembly.

- Docking of Different Space Vehicles: The docking of various space vehicles, such as crewed spacecraft, cargo ships, and scientific modules, demonstrates the versatility and critical importance of in-space assembly techniques. These docking maneuvers require precision and coordination, further emphasizing the need for robust infrastructure and advanced technology.

Policy and Permissions

The practice of in-space assembly, particularly when involving mission extension vehicles (MEVs) and other servicing technologies, necessitates clear policies and permissions from satellite and spacecraft owners. Establishing a regulatory framework is essential to ensure the smooth operation and collaboration between different stakeholders in space.

Infrastructure for In-Space Assembly

- Modular Design: The future of in-space assembly relies heavily on modular design principles. By developing standardized modules, we can ensure compatibility and ease of assembly. These modules can be easily docked and undocked, much like connecting LEGO pieces, allowing for flexible and scalable space infrastructure.

- Innovative Docking Systems: Similar to how different countries have various electrical plugs, space docking systems must be versatile enough to accommodate various designs. Innovations in docking technology are crucial for ensuring that modules from different manufacturers can connect seamlessly.

- Robotic Arms: Robotic arms play a pivotal role in in-space assembly. These advanced tools are designed to handle a wide range of payloads, providing the dexterity and precision needed to assemble complex structures in the microgravity environment of space.

Interchangeable Module Models

To maximize the efficiency of rescue and maintenance missions, it is essential to develop interchangeable module models. For example, a rescue vehicle should be capable of assisting any space station, whether it is owned by a government agency or a private company. This interoperability ensures that resources can be efficiently utilized across various missions and platforms.

General Components

- Antennas and Solar Panels: These critical components must be designed for compatibility with a wide range of satellites and space vehicles. Standardizing the design of antennas and solar panels facilitates easier upgrades and replacements, enhancing the longevity and functionality of space assets.

- Smaller Components: Components such as LIDAR systems and small valves should also be designed with interoperability in mind. By ensuring that these smaller parts can connect to different satellites, we can streamline maintenance and assembly processes, reducing costs and increasing operational efficiency.

Conclusion

In-space assembly is paving the way for a new era of space exploration and infrastructure development. By focusing on modular design, innovative docking systems, and interoperable components, we can build a sustainable and efficient space environment. This collaborative approach not only enhances the capabilities of space missions but also fosters international cooperation and technological advancement.

InSpaceAssembly, #SpaceInfrastructure, #ModularDesign, #SpaceDocking #RoboticArms, #SpaceExploration, #SpaceInnovation, #ISAM #SpaceTechnology, #FutureOfSpace, #InternationalSpaceStation, #SatelliteMaintenance, #SpaceCollaboration, #SustainableSpace #SpaceMissio