Introduction to In-Space Manufacturing

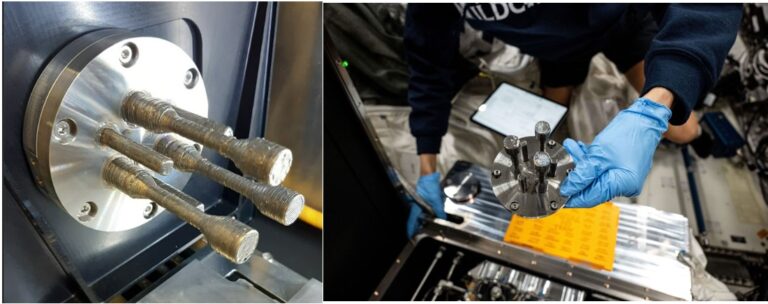

Picture: Metal3D printer test print, Credit ESA

In-space manufacturing represents the final and most critical component of the ISAM (In-Space Service, Assembly, and Manufacturing) framework. As the ultimate enabler of sustained space exploration, manufacturing in space overcomes the constraints of Earth-based production and allows for the creation of advanced tools, materials, and products in the unique microgravity environment of space.

Notable Achievements

- 3D Printing on the International Space Station (ISS): One of the most significant milestones in in-space manufacturing is the successful use of 3D printers on the ISS. NASA and Made In Space achieved a landmark breakthrough by producing the first 3D printed object in space in 2014, followed by the creation of critical tools and parts necessary for the station’s maintenance and operations. This advancement has proven the viability and utility of manufacturing in microgravity.

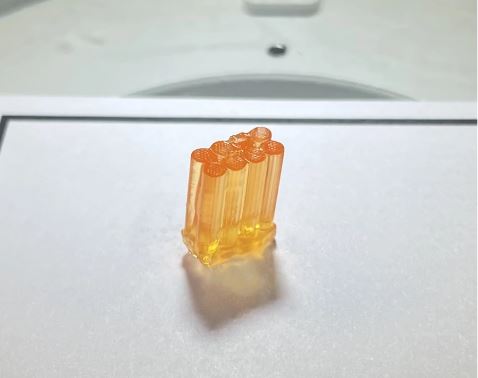

- Production of High-Quality Fiber Optics: The manufacturing of ZBLAN optical fiber in microgravity conditions has yielded higher quality fibers than those produced on Earth. This has the potential to revolutionize telecommunications and medical devices by providing superior performance materials.

Advantages of In-Space Manufacturing

- Eliminating Launch Constraints: Manufacturing in space eliminates the need for components to withstand the harsh vibrations and forces experienced during launch. This allows for the creation of more delicate and precise instruments that would be impossible to launch from Earth.

- Microgravity-Specific Tools: Tools and equipment designed specifically for microgravity can be more efficient and effective. This includes specialized manufacturing processes that leverage the unique conditions of space.

- Enhanced Quality of Products: Products such as cosmetics, pharmaceuticals, and proteins can be produced with higher quality in space due to the absence of gravity. This can lead to breakthroughs in medicine and other industries.

- Structural Manufacturing: The ability to build and assemble large structural components, like beams and frameworks, directly in space allows for more ambitious construction projects. These can be tested and validated in the same environment in which they will be used, ensuring greater reliability and performance.

- Future of Semiconductor Production: Semiconductor manufacturing in space could become practical and economical, leveraging the microgravity environment to create more efficient and powerful electronic components.

Applications and Future Prospects

- Mars Missions and Beyond: For long-duration missions, such as those to Mars, the ability to produce pharmaceuticals, surgical tools, and other medical supplies on-site is crucial. In-space manufacturing can ensure that astronauts have access to necessary medical care without relying on resupply missions from Earth.

- Sustainable Space Colonies: As we establish more permanent human presence in space, the ability to manufacture essential goods locally will be key to sustainability. This includes everything from building materials to everyday necessities.

- Economic Impact: The development of a robust in-space manufacturing sector has the potential to create new markets and industries, driving economic growth and innovation both in space and on Earth.

Conclusion

In-space manufacturing is poised to transform the future of space exploration and utilization. By overcoming the limitations of Earth-based production and leveraging the unique conditions of space, we can create higher quality products, ensure the sustainability of long-term missions, and open new frontiers for economic and technological development. As we continue to develop and refine these capabilities, the possibilities for what we can achieve in space are limitless.

InSpaceManufacturing, #SpaceExploration, #ISAM, #3DPrintingInSpace, #SpaceTechnology, #Microgravity, #SpaceInnovation, #SpaceSustainability, #FutureOfSpace, #SpacePharmaceuticals, #SpaceConstruction, #MarsMissions, #SpaceEconomy, #SpaceColonies, #MadeInSpace