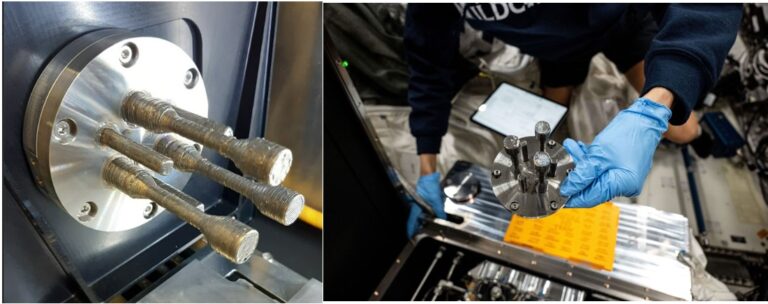

In-space manufacturing has a rich history of technological experiments that laid the foundation for today’s operational systems. While many of these technologies are no longer in use, their contributions to the field remain invaluable. This article delves into some of the key in-space manufacturing experiments from the past that are no longer operational today. Photo: Protein Crystallization Facility hardware Credit:NASA

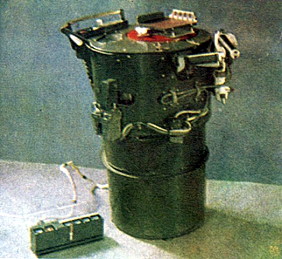

1. Welding on Soyuz 6 (1969)

In 1969, Soviet cosmonauts conducted the first in-space welding experiments aboard the Soyuz 6 mission. Using the Vulkan welding apparatus, they tested three different welding methods: electron beam welding, low-pressure plasma arc welding, and high-pressure arc welding. This experiment demonstrated that welding in space was feasible, paving the way for future construction and repair tasks in microgravity.

VULKAN: First welding machine used on space and first In-Space Manufacturing practice.

2. Skylab Materials Processing Laboratory (1973-1974)

NASA’s Skylab, America’s first space station, housed a Materials Processing Laboratory that conducted a variety of materials science experiments. Notable among these were:

- Electrophoresis Operations in Space (EOS): Focused on separating biological materials, electrophoresis in microgravity allowed for higher purity and better yield than Earth-based processes.

- Crystal Growth Experiments: Aimed at understanding how microgravity affects the growth of crystals, these experiments were critical for developing advanced materials and pharmaceuticals.

3. Space Shuttle Experiments (1981-2011)

The Space Shuttle program carried out numerous in-space manufacturing experiments over its three-decade tenure, including:

- Continuous Flow Electrophoresis System (CFES): This system was used to separate biological materials in the microgravity environment, producing results that were not achievable on Earth.

- Materials Science Laboratory-1 (MSL-1): Conducted aboard the Space Shuttle Columbia, MSL-1 investigated the properties of metals and alloys in microgravity, contributing valuable data on material behavior.

4. Vibrations of Welds (VIB) on Mir and ISS

The VIB experiment series on the Russian Mir space station and later on the International Space Station (ISS) focused on understanding the properties of welds in space and how vibrations affected the welding process. Although these experiments are no longer ongoing, they provided critical insights into in-space construction techniques.

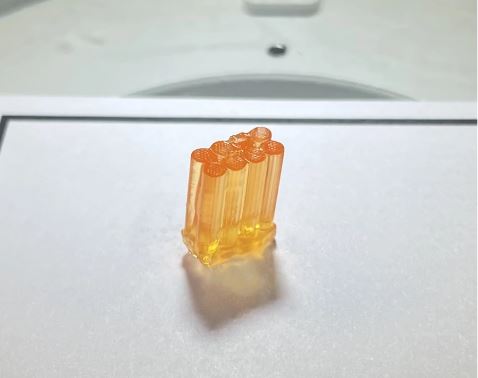

5. Protein Crystal Growth Experiments (1990s-2000s)

Throughout the 1990s and early 2000s, NASA and international partners conducted numerous protein crystal growth experiments on various space missions, including the ISS. These experiments aimed to grow high-quality protein crystals in microgravity, leading to advances in drug development and materials science. Although the specific experimental setups are no longer in use, they were crucial in demonstrating the benefits of microgravity for crystallization processes.

6. EURECA (European Retrievable Carrier) (1992-1993)

Launched by the European Space Agency (ESA) and retrieved by NASA’s Space Shuttle, EURECA hosted a variety of materials science and biology experiments in microgravity. Among these were:

- Advanced Gradient Heating Facility (AGHF): Used for studying the solidification processes of various materials.

- Protein Crystallization Facility (PCF): Conducted experiments on protein crystal growth, which provided insights into the development of pharmaceuticals.

7. Spacelab Missions (1983-1998)

Spacelab, a reusable laboratory flown on Space Shuttle missions, facilitated numerous experiments in materials science and biology. Key experiments included:

- Crystallization in Microgravity: Aimed at understanding how the absence of gravity affects crystal growth.

- Fluid Physics Experiments: Investigated the behavior of fluids in space, essential for developing in-space manufacturing processes.