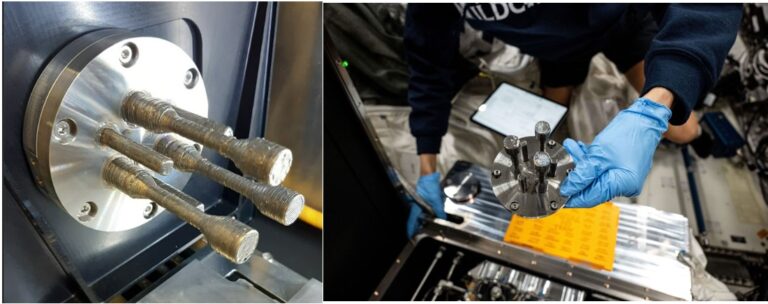

In-space manufacturing (ISM) is critical for building a sustainable future in space, and a new breakthrough in welding technology marks an important step forward. Recently, ESA, in collaboration with NASA and ThinkOrbital, tested an autonomous welding machine in space—an experiment that could redefine how we build and maintain structures in orbit. Photo Credit: ESA/NASA

Why Welding in Space Matters

Welding is one of the cornerstones of terrestrial construction, but it’s never been widely applied in space. Surprisingly, even the 450-tonne International Space Station (ISS) was entirely pre-fabricated on Earth, with components bolted together in space. Welding has only ever been performed experimentally in orbit, the last time being over 40 years ago.

The new experiment, carried out aboard a SpaceX Falcon 9 mission, used electron beam welding, which is ideal for space’s vacuum environment. Unlike welding on Earth, where gravity and convection currents influence the behavior of molten metals, in microgravity, molten metals behave more like liquid blobs, shaped primarily by surface tension. This experiment helps scientists understand how space-specific conditions—such as microgravity, radiation, and vacuum—affect material properties during welding.

The Importance of Real Space Data

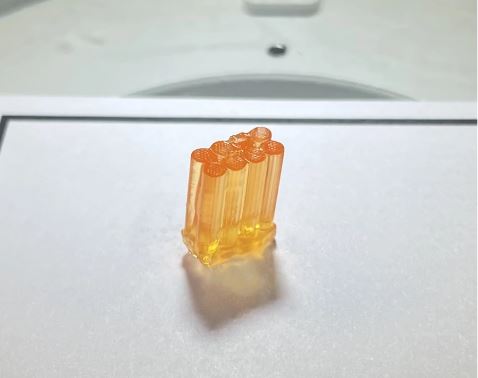

ESA Materials Engineer João Gandra emphasizes the need for real-world data: “We can run computer simulations, but we lack empirical data to calibrate and improve our predictions.” This new space-welded sample, which is just a single centimeter across, will be compared to identical welds performed on Earth. The ESA lab is meticulously examining these samples using X-ray tomography, hardness tests, and other cutting-edge techniques. This data is essential for advancing our understanding of how materials behave in space.

A Tool for the Future Space Economy

As in-space service, assembly, and manufacturing (ISAM) grow, welding will be crucial for building and maintaining infrastructure in space, from space stations to spacecraft repairs. This experiment is part of a broader effort to create tools for the emerging space economy, where sustainable human activities beyond Earth will require efficient, autonomous solutions.

Beyond welding, the system tested in space could be used for cutting, 3D printing, and other vital construction tasks. ESA and NASA’s involvement signals how serious the industry is about moving toward fully operational in-space manufacturing capabilities.

Next Steps

The welded samples have been returned to Earth for further analysis, but this is just the beginning. ThinkOrbital and ESA plan to participate in more ambitious welding tests in the future. This aligns with ESA’s strategy for in-space manufacturing and servicing, which will be key for supporting long-duration missions and deeper space exploration.

As we move closer to a future where ISAM becomes commonplace, in-space welding will play an essential role in constructing habitats, maintaining spacecraft, and assembling the infrastructure needed for human expansion beyond Earth.